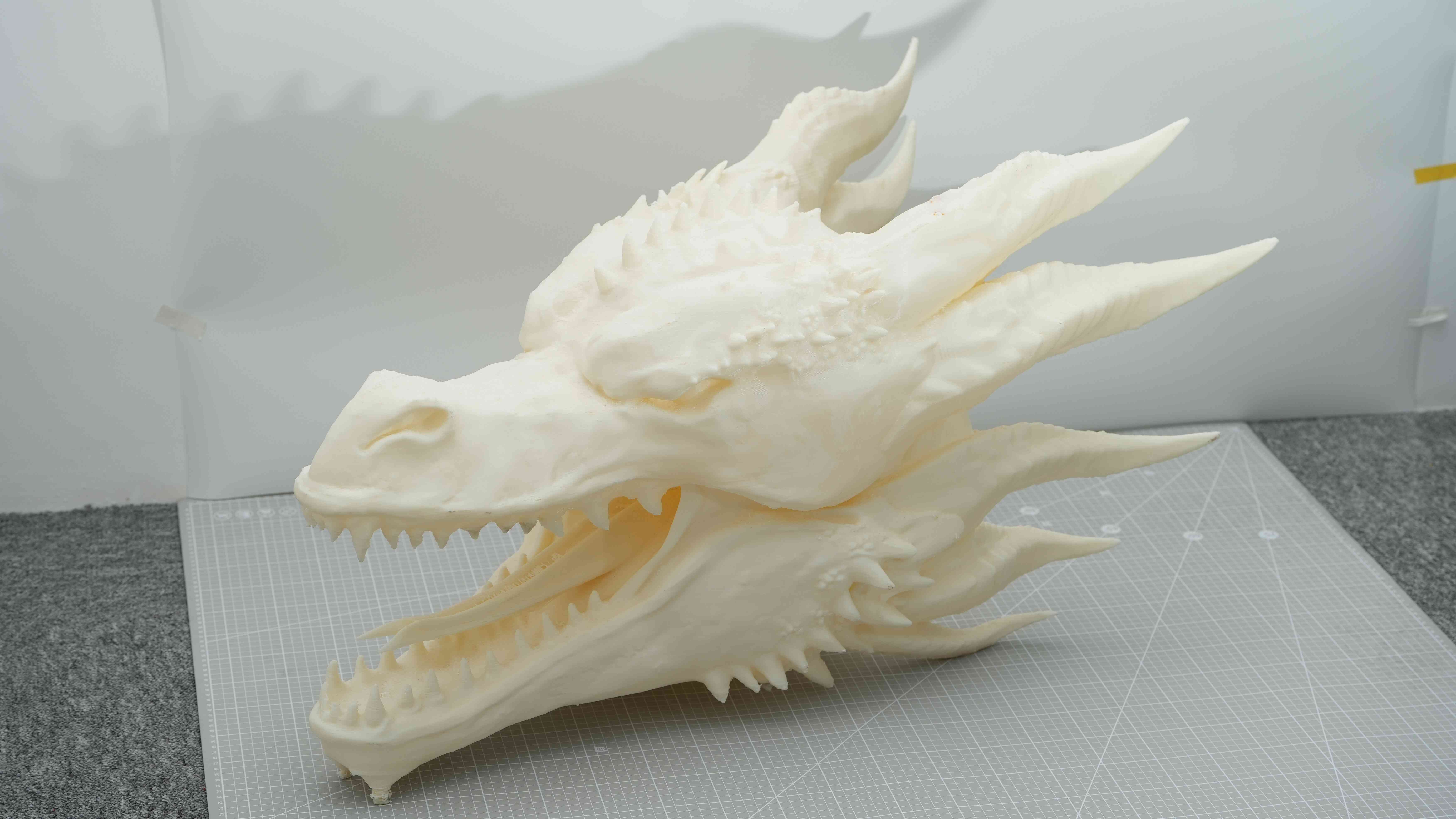

Stereolithography (SLA) 3D Printing Service

Visual prototyping

• Tolerance ± 200μm or 0.2%mm

• Lead times from 2 business days

• Minimum Layer Thickness 0.6 mm

Online Custom Parts 3D Printing ServiceReceive immediate online quotations for parts in more than 70 metal and plastic materials.

See our 3D printing services

Stereolithography (SLA) 3D Printing Service

Visual prototyping

• Tolerance ± 200μm or 0.2%mm

• Lead times from 2 business days

• Minimum Layer Thickness 0.6 mm

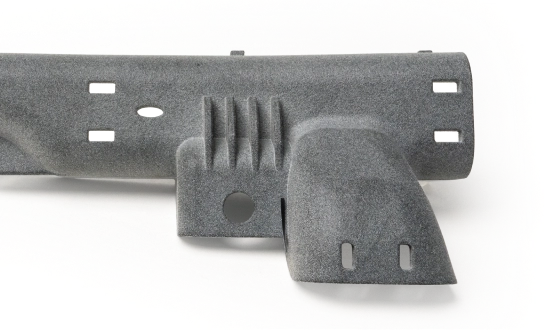

Selective Laser Sintering (SLS) 3D Printing Service

Functional prototyping & low-run production

• Tolerance ± 300μm or 0.3%mm

• Lead Time 48 hours or 72 hours

• Minimum Layer Thickness 0.8 mm

HP Multi Jet Fusion (MJF) 3D Printing Service

Functional prototyping & low-run production

• Tolerance ± 300μm or 0.3%mm

• Lead Time 48 hours or 72 hours

• Minimum Layer Thickness 0.8 mm

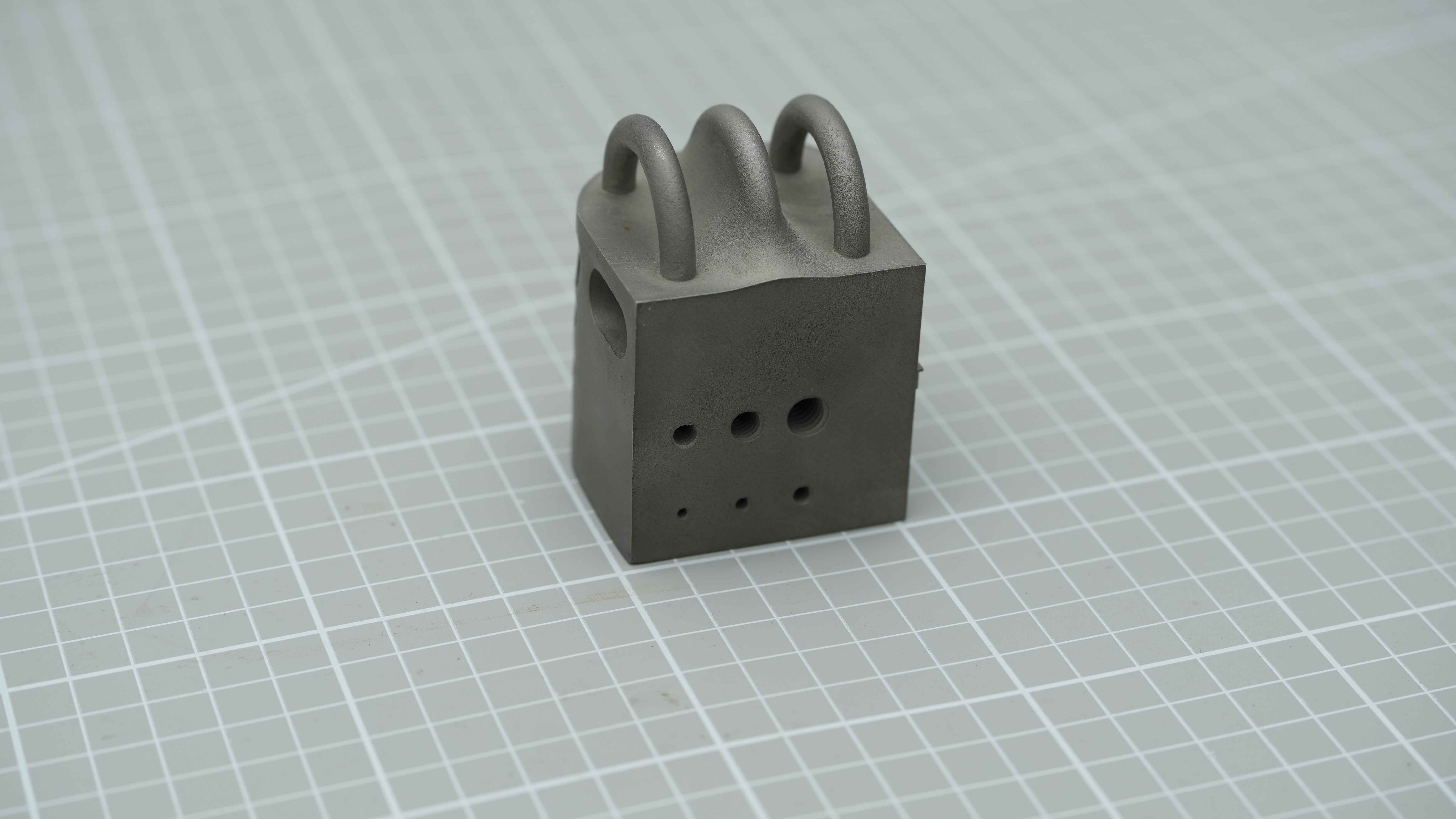

Selective Laser Melting (SLM) 3D Printing Service

Functional prototyping & high-precision metal part production

• Tolerance ± 200μm or 0.2%mm

• Lead Time 7 Business Days

• Minimum Layer Thickness 1 mm

Fused Granular Fabrication (FGF) 3D Printing Service

Large-format model fabrication & plastic pellet extrusion printing

• Nozzle range: 0.3-8mm

• Lead time: 5-10 business days

• Minimum layer thickness: 0.3mm-6mm

Fused Deposition Modeling (FDM) 3D Printing Service

Fast & affordable prototyping

• Tolerance ± 200μm or 0.2%mm

• Lead Time 4 Business Days

• Minimum Layer Thickness 0.254 mm

Vacuum casting

Low-volume production & mold-based prototyping

• High dimensional accuracy and low cost.

• Material flexibility. A variety of vacuum casting materials with various colors are available and accessible, meeting the needs of different applications.

• Parts with complex structures and intricate details can be created by vacuum casting easily and efficiently

CNC/Sheet Metal/Injection MoldingReceive immediate online quotations for parts in more than 70 metal and plastic materials.

See our CNC/Sheet Metal/Injection Molding services

CNC Machining

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to form designs from metal or plastic stock. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers.

Sheet and Tube Fabrication

Sheet Metal Fabrication/ Sheet Cutting/ Laser Cutting/ Waterjet Cutting/ Laser Tube Cutting/ Tube Bending

Plastic injection molding

Injection molding is the manufacturing process of injecting high-pressure thermoplastic into a mold. Ideal for high-volume production.

Insert molding

A manufacturing process in which a part is molded around a pre-installed insert in the tooling.

CNC Milling

A variety of custom CNC milled parts, including metal and plastic, options are available for an online quote.

Overmolding

A manufacturing process in which one plastic material is molded over another to create a single component.

CNC Turning

CNC turned prototypes and production parts in days | AS9100D | ISO 9001:2015 | ISO 13485 | IATF 16949:2016 | ITAR Registered | Free standard shipping on all CN orders

Liquid silicone rubber molding

A thermoset process that involves mixing a two-part solution together to produce flexible and durable parts.

Why OLA Manufacturing?

OLA3DP is a world-leading digital manufacturing source for rapid prototypes and on-demand production parts.

Our automated quoting and manufacturing systems enable us to produce commercial-grade plastic, metal, and liquid silicone rubber parts in a matter of days.

Quality is the first in OLA. From the raw material to the last QC process, all with certificated assurance.

With us, you can shorten your speed to market, and better manage the demand volatility of your product life cycle. We control the cost in every process to offer our customer affordable price.

View more about our supply chain

800+

Industry Machines

Instant quotes for

1-1,000 parts

99.9%

On time performance

Lead times from

1 business day

Trusted by Businesses Around the World

OLA3DP is proud to be the leading on-demand manufacturing platform, helping suppliers to uncover profitable opportunities, source affordable raw materials and tooling, and streamline cash flow and shop efficiency.

OLA Business

We specialize in in-house production of SLA, SLS, and SLM parts through our own manufacturing facilities. Additionally, we have curated a network of high-quality

domestic suppliers in China to provide expanded process technology options.

Our StandardGuaranteed quality, every time.

Tolerances

Our manufacturing partners adhere to industry standards* for threads and tolerances.

Finishing

Our manufacturing partners follow our strict technical requirements for finishing and post-processing.

Cerification

Our quality management system is ISO 9001 certified and our manufacturing partners can provide additional certifications: AS 9100, ISO 9001, ISO 13485, IATF 16949.

Inspection

Our manufacturing partners adhere to industry standards* for threads and tolerances.

Quality Documentation

We provide quality documentation

Such as First Article Inspection, Certificate of Conformance and Material Certificate/Test Report on request.

Refunds

Are your parts not up to spec? We’ll reorder them for you for free, or provide a full refund.

Ordering Process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Blog

Metal 3D Printing Guide: SLM Technology for End-Use Parts | OLA

OLA's SLM metal 3D printing produces end-use parts with 99.97% density. Certified for aerospace and medical applications. Get CNC-finished titanium/aluminum parts in 10 working days.

Read more

MJF vs SLS: Choosing the Right Nylon 3D Printing Technology | OLA

Professional guide: Choose between MJF and SLS for nylon parts. OLA's 3D printing factory in China offers both technologies with 48-hour turnaround. Get instant quoting for your project.

Read more

5 Key Advantages of SLA 3D Printing for Prototyping | OLA China

OLA provides industrial SLA 3D printing services in Shenzhen with 0.05mm precision. Get functional prototypes in 7 days using 20+ engineering resins. Free DFM analysis included.

Read more

FAQWelcome to the FAQ section of OLA Manufacturing Platform! Here are some answers to frequently asked questions about our platform and the services we offer for the 4 industries we manage: 3D printing, Injection molding, CNC Machining, and Sheet metal fabrication.

What industries do you serve?

We serve aerospace, automotive, healthcare, and consumer goods. Specialized in medical implants, lightweight aerospace brackets, and custom automotive tooling.

Surface finishes / quality levels (EC, BC, FC): For which technologies do these apply?

- EC (Economic): SLS/MJF – standard matte finish.

- BC (Business): SLA with manual polishing (±0.1mm).

- FC (First Class): SLM with mirror electroplating.

What does surface finishing mean?

OLA Surface finishing enhances aesthetics and functionality. Options include:

- Mechanical: Sanding, polishing.

- Chemical: Vapor smoothing, electroplating.

- Coatings: Paint, conductive layers.

Do you support functional prototyping or end-use parts?

Yes! (SLM/MJF) produces end-use parts like turbine blades and automotive jigs. Prototypes use cost-efficient (SLS/PLA).

What are the maximum/minimum part sizes?

- Max: FGF (2m length), SLM (300x300x300mm).

- Min: SLA (0.2mm wall thickness).

Can you print multi-material or color parts?

Yes! MJF supports grayscale/color parts, and multi-material FDM combines plastics/rubbers.